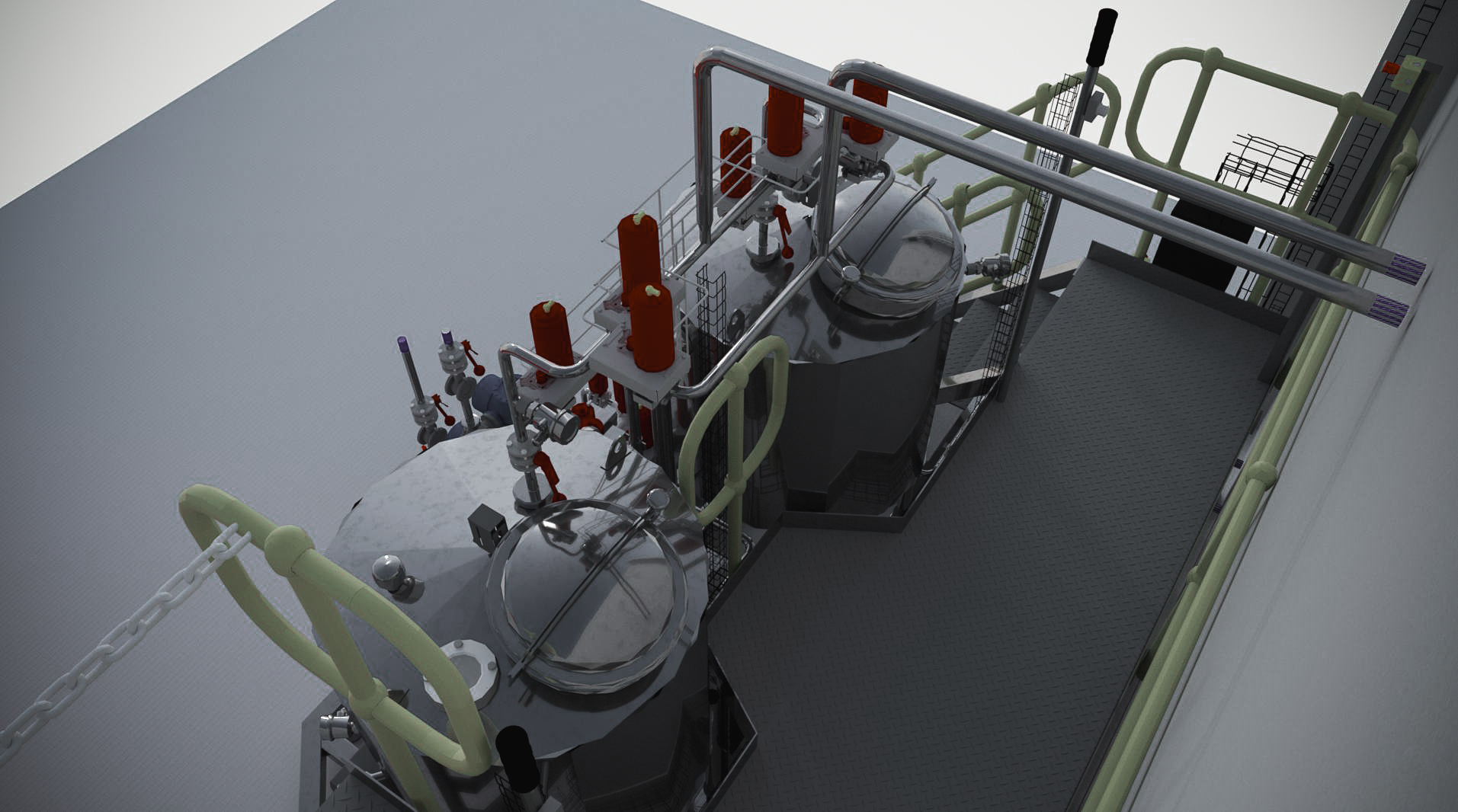

At Axxello, we recently undertook an exciting project to design and implement a state-of-the-art 2-tank kettle enzyme dosing system for one of our valued brewing clients. This turnkey solution was developed to facilitate the precise make-up and dosing of tannins in their brewing process, specifically targeting Wort Copper 1 and 2. Our comprehensive approach and advanced engineering solutions ensure that the client can achieve optimal brewing efficiency and product quality.

Our expert team at Axxello designed the system to allow for the seamless make-up and dosing of tannins, utilizing a single tannin dosing line for both tanks. We ensured that the tannins, introduced manually through 25 kg bags, could be effectively managed.

In addition to the efficient make-up and dosing capabilities, Axxello integrated a robust Cleaning-In-Place (CIP) process for the tannin dosing tanks and lines. This ensures thorough cleaning in sync with the selected Wort Copper’s CIP schedule, maintaining high hygiene standards and operational integrity. With our expertise, the client now benefits from a reliable, high-performance enzyme dosing system that enhances their brewing process, demonstrating Axxello’s commitment to delivering tailored solutions that meet our clients’ unique needs.